News

Sales and Trading of Sand Screening Machines and Sand Separation Equipment at Competitive Prices – 0906 601 755

Sales and Trading of Sand Screening Machines and Desanders in Hanoi for Bored Pile Drilling and Bentonite Filtration – Best Prices on the Market.

In bored pile drilling and Bentonite slurry treatment, choosing the right sand screening machine not only improves construction efficiency but also significantly reduces filtration and material recirculation costs. For more than a decade, Hanoi Vietnam Co., Ltd. has been a trusted and reputable brand for both domestic and international customers. We currently provide sand screening and sand separation (desanding) machines with capacities from 80 m³/h to 250 m³/h, effectively serving projects ranging from small civil works to key infrastructure developments. All equipment is directly imported from overseas, genuine products with competitive pricing.

We are committed to delivering the best service, fast and simplified purchasing procedures, and the most competitive prices for sand screening machine trading in Hanoi and nationwide.

What Is a Sand Screening Machine?

A sand screening machine is specialized equipment widely used in the construction industry, especially in foundation works and bored pile drilling. Its primary function is to separate solid particles of different sizes from slurry mixtures—typically drilling slurry such as Bentonite. As a result, the machine helps reuse the slurry efficiently, reduces waste, and ensures construction quality.

Structurally, a sand screening machine typically consists of a screening frame, screening mesh (single-deck or multi-deck), a vibration-generating unit (usually a vibration motor or rotating shaft), a feed hopper/chute, and a discharge system for solids. With this design, when slurry containing sand and mud is fed into the machine, the vibration or rotation causes particles larger than the mesh openings to be retained, while the slurry and finer particles pass through and are collected for reuse.

On today’s market, sand screening machines are available in multiple types based on capacity, screening method (vibratory or rotary), number of screen decks, and the ability to integrate additional treatment systems such as recirculation pumps or centrifuges. This allows users to flexibly select equipment suitable for the scale and characteristics of each specific project.

Beyond bored pile drilling, sand screening machines are also used for sand processing in construction material extraction, industrial waste treatment, and concrete block production. Thanks to their wide applicability and proven efficiency, sand screening machines have become essential equipment in modern construction fleets.

Operating Principle of Bentonite Filtration Systems

In bored pile drilling projects using Bentonite slurry, reusing slurry after it becomes contaminated with impurities is a critical technical step. If slurry is not properly treated, particles such as mud, sand, and soil debris can reduce borehole wall stability and may even cause borehole collapse—directly affecting construction quality.

Bentonite filtration systems are designed to solve this issue by removing solid impurities larger than the allowable threshold. The main operating principle relies on particle size classification using screen meshes together with vibration or rotation:

- Slurry is pumped into a separation tank or screening system

- Larger particles such as sand and gravel are retained on the screen

- Slurry containing finer particles is recovered for reuse

- In premium models, a built-in centrifuge system is integrated to separate even finer particles, ensuring maximum slurry purity

This mechanism not only reduces Bentonite material costs but also protects surrounding geological conditions and minimizes construction risks. Modern filtration machines are also equipped with automation features, enabling continuous operation and easy quality control.

Comparison: Vibratory Screen vs. Rotary Screen

Sand screening machines on the market are generally divided into two main types: vibratory screening machines and rotary screening machines. Each type has its own operating principle, advantages, and limitations, suitable for different construction requirements.

Vibratory screens use vibration motors to generate strong oscillations, allowing material to move quickly across the screen surface. As a result, they can process large slurry volumes in a short time, making them suitable for projects with high demands for schedule and screening accuracy. Their compact structure is also an advantage when working in limited spaces or when frequent relocation is required.

In contrast, rotary screens operate based on the rotation of a cylindrical drum screen. Material is fed into the drum and gradually screened during rotation. This type is suitable for coarse materials or mixtures with a high solid content; however, its larger size and slower processing speed make it less suitable for high-capacity projects.

| Criteria | Vibratory Screen | Rotary Screen (Drum Screen) |

|---|---|---|

| Operating Mechanism | High-frequency screen vibration | Rotating drum screen; material falls gradually |

| Separation Efficiency | High, fast, time-saving | Moderate; suitable for coarse materials |

| Machine Size | Compact, easy to relocate | Bulkier and heavier |

| Maintenance | Requires periodic screen cleaning | Easy routine maintenance but harder parts replacement |

| Common Applications | Bored pile drilling, Bentonite filtration | Sand/gravel and aggregate screening in extraction |

Depending on project conditions and material characteristics, selecting the right machine type will directly impact both technical performance and economic efficiency.

How to Select the Right Capacity for Your Project

Choosing the capacity of a sand screening machine should not be based solely on price. It requires consideration of multiple technical and practical factors. Each project has different scale, conditions, and slurry treatment volume, so selecting the wrong capacity can lead to machine overload or unnecessary investment.

First, consider the daily slurry volume to be treated. Small projects such as residential houses or isolated bored piles may only require an 80 m³/h machine. However, for bridge works, high-rise buildings, or industrial zones, machines in the 180–250 m³/h range are recommended to ensure sufficient throughput.

Second, consider the required slurry reuse quality. If high slurry purity is required (especially for Bentonite), it is recommended to use machines integrated with a centrifuge unit or multi-deck fine screening systems. These models can remove fine silt particles that conventional screens cannot effectively separate.

In addition, site conditions also matter: compact machines are more suitable for constrained sites where bulky equipment cannot be installed. Do not forget to check the available power supply, as larger machines typically require 3-phase power and higher operating capacity—leading to higher running costs.

Finally, the best recommendation is to consult directly with the supplier or foundation construction contractors for project-specific guidance. Investing in the right machine from the beginning helps reduce risks, save time, and improve overall efficiency.

Effective Maintenance Tips for Desanders

Sand screening machines operate continuously under harsh conditions, frequently exposed to water, sand, soil, and chemical slurries such as Bentonite. Without proper maintenance, machines can easily break down, causing construction delays and costly repairs.

First, cleaning the screen mesh after each shift is mandatory. If residues and sediments accumulate over time, vibration performance decreases and the screen may clog, causing a serious drop in filtration efficiency. Using a high-pressure water jet is an effective way to clean quickly without damaging the mesh surface.

Second, routinely inspect and lubricate moving components such as bearings, belts, and rotating shafts. These parts are most prone to wear, especially in dusty or humid environments. Use specialized grease and perform weekly inspections.

In addition, replace screen meshes with the correct specifications. Non-standard or improvised meshes can reduce screening efficiency and may even damage the vibration unit. When replacing the mesh, also check the screen frame condition to avoid deformation.

If the machine is not used for a long period, store it in a dry place, cover it with a tarp, and drain all remaining slurry from the system to prevent corrosion. Keeping maintenance records and operation logs also helps track machine condition and detect abnormalities early.

Regular maintenance not only extends machine service life but also ensures stable operational efficiency and helps owners minimize costs.

Popular Sand Screening Machine Lines at Hanoi Vietnam

| Model | Filtration Capacity | Screen Deck | Screen Type | Main Applications |

|---|---|---|---|---|

| HNV-80 | 80 m³/h | 1 deck | Vibratory | Residential projects, small bored piles |

| HNV-120 | 120 m³/h | 2 decks | Vibratory + centrifuge | High-rise buildings, advanced civil works |

| HNV-180 | 180 m³/h | 2–3 decks | Vibratory + fine filtration | Industrial zones, urban projects |

| HNV-250 | 250 m³/h | 3 decks | High-frequency vibratory | Bridge and road projects, major infrastructure |

All machines are imported from reputable brands in China, Korea, and Japan, with full CO/CQ documentation and lifetime technical support.

Sand Screening Machine Sales and Rental Services in Hanoi

With more than a decade of experience in supplying foundation construction equipment, Hanoi Vietnam Co., Ltd. is proud to be a leading provider in Northern Vietnam, offering sales and rental services for specialized sand screening and sand separation machines for projects of all sizes. We understand that equipment requirements vary from one project to another, so our sales and rental policies are always designed flexibly to best meet real customer needs.

Sand Screening Machine Sales – Genuine Products with Full Documentation

All sand screening machines at Hanoi Vietnam are fully imported units from major brands in China, Korea, and Japan. Each product comes with:

- Full certificates of origin (CO) and quality (CQ)

- VAT invoices and clear contracts

- Detailed technical guidance and installation videos

- Warranty commitment of 6–12 months depending on model

We keep stock available at our Hanoi warehouse for fast delivery, and can provide on-site engineer support if required.

Sand Screening Machine Rental – Flexible by Day, Week, or Month

Hanoi Vietnam’s sand screening machine rental service is ideal for short-term projects or contractors aiming to reduce initial investment costs. We provide:

- Daily/weekly/monthly rental packages including necessary accessories

- Two-way transportation support to the construction site

- Machine handover with on-site engineers for operation guidance

- On-site maintenance and servicing upon request

All rental machines are inspected, cleaned, and test-run before delivery to ensure maximum safety and efficiency in operation.

Why Choose Hanoi Vietnam?

- Best market prices with no intermediaries

- Ready stock available—no waiting for import

- Consultation to select the most suitable model for each project type

- 24/7 technical support, fast on-site maintenance

Whether you are a major contractor or an individual working on civil construction, Hanoi Vietnam is always ready to accompany you on every project—from equipment supply to full-package technical support.

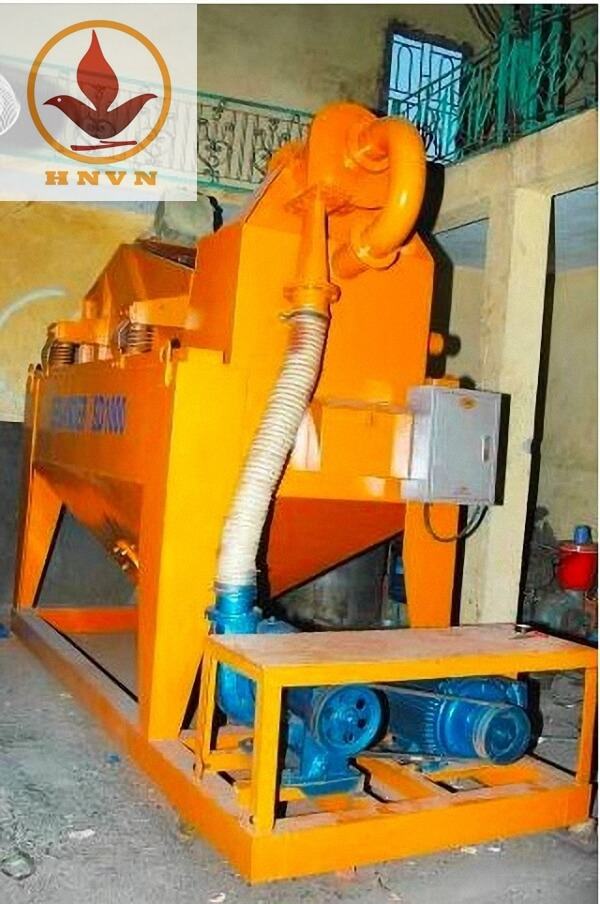

Images of the Desander SD 1000 Sand Screening & Separation Machine

If you need to purchase sand filtration machines, sand separation machines, or sand screening machines, please call us now at 0906 601 755. Thank you very much.

Please refer to some specialized sand screening machine models below:

*Liên hệ nhận thông tin và báo giá: https://mayxaydunghanoi.click/