Kobelco BM700C crawler crane – European version

- Model: Kobelco BM700C

- Version: Upgraded EU Version

- Maximum lifting capacity: 80 tons

- Boom length: 33 m

- Engine: Mitsubishi 6D24

- Year of manufacture: 2001

- Hooks: 2 hooks

The Kobelco BM700C crawler crane features an 80-ton lifting capacity, an upgraded undercarriage designed for the European market, and is well-suited for foundation works and heavy structural construction.

Selecting a crawler crane for foundation projects, heavy material handling, or steel structure erection requires careful consideration of lifting capacity, stability, fuel consumption, and performance on complex terrain. In Vietnam in particular—where construction sites are often confined, ground conditions are weak, and continuous heavy lifting is required—contractors place great emphasis on long-term operating reliability and mechanical durability.

A detailed analysis of the Kobelco BM700C crawler crane is therefore essential, especially since this model is an upgraded version for the European market, incorporating multiple improvements compared to cranes in the same segment such as the Kobelco 7080 or older Sumitomo and Hitachi models. This article focuses on its structure, powertrain, travel system, engine, operational advantages, application scenarios, and practical advice when selecting this machine.

Hanoi Vietnam provides an in-depth analysis of the technical specifications, real-world performance, operating costs, and comparisons with other crawler cranes to help engineers and investors make informed decisions.

Detailed overview of the Kobelco BM700C crawler crane

The Kobelco BM700C crawler crane is a medium-to-heavy lifting machine from Kobelco’s upgraded generation, designed for the European market with strict requirements for safety, durability, and stability when handling heavy loads. Although positioned in the 80-ton class, the BM700C stands out due to its superior lifting chart compared to the well-known Kobelco 7080—especially at longer working radii and extended boom lengths. This makes the BM700C particularly suitable for projects requiring stable heavy lifting, such as port construction, industrial plants, steel module erection, and mass pile foundation works.

The Kobelco BM700C uses a Caterpillar-type crawler undercarriage with wider tracks than standard models, allowing more even ground pressure distribution and reducing settlement when working on soft ground. This design offers a clear advantage over wheeled cranes and older crawler cranes that lack sufficient stability on weak terrain.

Another notable feature is the Mitsubishi 6D24 engine—widely regarded as extremely robust in the construction machinery industry. This engine offers high durability, ease of maintenance, and widely available spare parts in Vietnam, resulting in lower operating costs compared to cranes equipped with newer Cummins or Hino engines.

Additionally, the BM700C is equipped with a dual-hook system, enabling flexible lifting configurations for handling large loads as well as auxiliary lifting tasks. With a standard boom length of approximately 33 meters, the crane performs well across most construction scenarios, including material lifting, structural erection, and pile installation using vibratory hammers. Its optimized design allows long continuous operation while maintaining high stability.

Technical specifications of the Kobelco BM700C crawler crane

| Specification | Value |

|---|---|

| Model | Kobelco BM700C |

| Version | Upgraded EU Version |

| Maximum lifting capacity | 80 tons |

| Boom length | 33 m |

| Engine | Mitsubishi 6D24 |

| Year of manufacture | 2001 |

| Track type | Caterpillar-type, extended track width |

| Hooks | Dual hooks |

| Main applications | Structural lifting, pile works, heavy material handling |

Structural design and outstanding technical features of the Kobelco BM700C

When evaluating a crawler crane, the overall structure and undercarriage design directly determine lifting capacity, stability, and service life. The Kobelco BM700C follows a “stability on all terrains” design philosophy, suitable for both European job sites and soft-ground conditions common in Southeast Asia. Its reinforced steel undercarriage provides higher torsional rigidity than the BM700B, reducing twisting and vibration when lifting heavy loads—especially at large boom angles or in windy conditions.

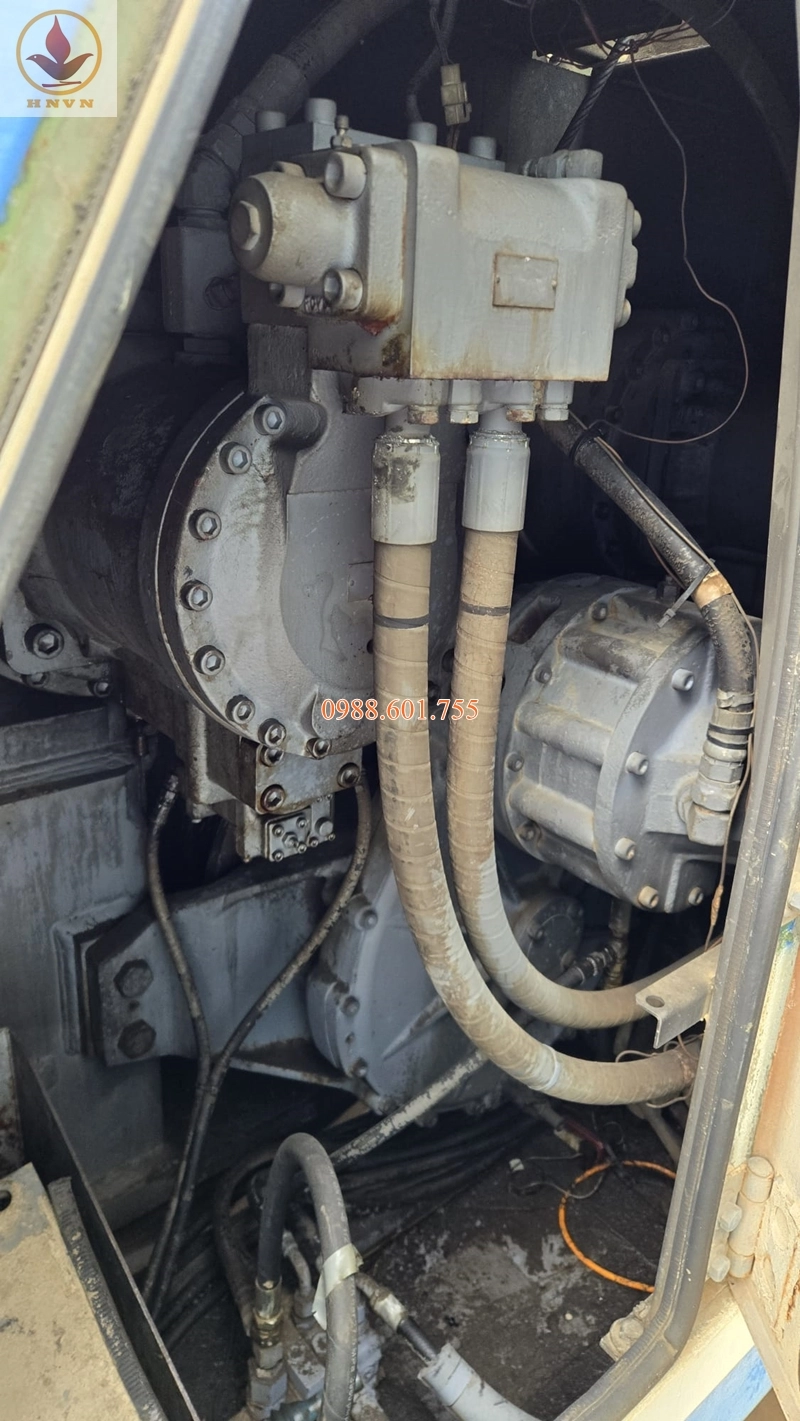

The Caterpillar-style track system increases ground contact area, lowering ground pressure and improving mobility on soft or muddy terrain. Rollers, track shoes, and drive sprockets are durable and easy to replace, with parts compatible with many Caterpillar machines commonly used in Vietnam.

The Mitsubishi 6D24 engine delivers strong torque and stable performance during continuous heavy lifting. Known for its excellent heat resistance and suitability for hot, dusty job sites, this engine contributes significantly to the BM700C’s reputation as one of the most reliable 80-ton crawler cranes on the used-equipment market today.

Comparison between the Kobelco BM700C and Kobelco 7080 and similar models

Comparing the Kobelco BM700C with other cranes helps contractors choose the right equipment. In the 70–80-ton segment, the Kobelco 7080 is well known, but engineers often rate the BM700C higher due to its superior lifting chart. At similar boom lengths of 30–33 m, the BM700C offers better lifting performance at working radii of 10–14 m—critical for confined industrial projects.

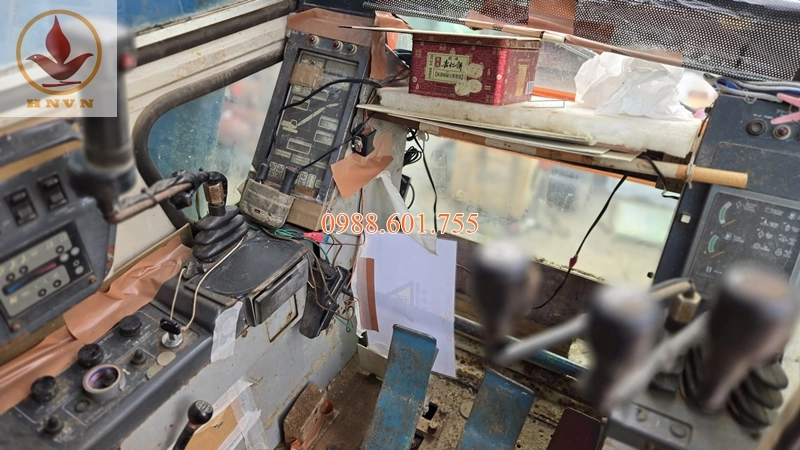

Compared with older models such as the Sumitomo LS118 or Hitachi KH300, the BM700C stands out with a stronger engine, more efficient hydraulic system, better visibility cabin, and fewer long-term reliability issues. While newer electronic-controlled models like the Kobelco CKE800 offer advanced technology, the BM700C excels in simplicity, lower operating costs, and long-term mechanical stability.

Practical applications of the Kobelco BM700C crawler crane

In foundation and infrastructure construction, the Kobelco BM700C is widely used for heavy lifting, pile works, material handling, and steel erection. Its 80-ton capacity and strong lifting chart make it ideal for ports, industrial plants, bridges, and heavy infrastructure projects. On soft ground, the Caterpillar-type tracks ensure stable operation with minimal settlement.

The crane is also commonly used for pile installation with vibratory hammers weighing 35–45 tons, making it popular for riverbank reinforcement, inland ports, and urban foundation works. Its reliability, fuel efficiency, and durable engine make it suitable for continuous day-and-night operation.

Guidelines for selecting the Kobelco BM700C for different projects

When choosing the Kobelco BM700C, contractors should assess lifting requirements, site conditions, and project duration. The crane is particularly effective for industrial plants, steel structure erection, pile foundation works, and bridge construction—especially on weak soil conditions.

For long-term projects requiring continuous operation, the Mitsubishi 6D24 engine provides significant advantages in durability and ease of maintenance. Compared with renting newer high-tech cranes, the BM700C offers better long-term cost efficiency. Prior to purchase or rental, contractors should carefully inspect the lifting chart, maintenance records, hydraulic system, and track wear to ensure optimal performance.

Conclusion

The Kobelco BM700C crawler crane is one of the most reliable choices in the 80-ton class for foundation works, bridge construction, port projects, and heavy steel erection. With its European-market upgrades, reinforced undercarriage, strong lifting chart, and durable Mitsubishi 6D24 engine, the BM700C delivers excellent performance under Vietnamese job-site conditions. When properly selected and maintained, it provides high economic efficiency, cost savings, and reliable project progress.

🌍 Website: https://mayxaydunghanoi.com

📲 Facebook: https://www.facebook.com/khoandapcap

📞 Call: Ms. Thùy Linh – 0899 601 755

📩 Email: hanoi.thuylinh2@gmail.com

*Liên hệ nhận thông tin và báo giá: https://mayxaydunghanoi.click/

Reviews

There are no reviews yet.